Overview

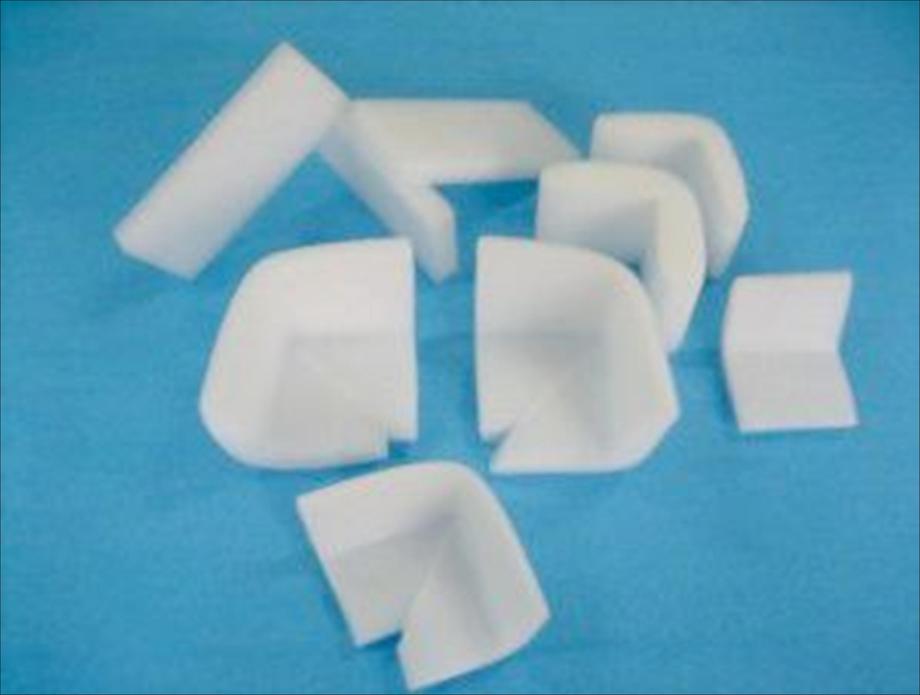

l EPE plank die-cut product is made from multiple layers of EPE foam, trimmed and then die-cut to finish. It pertains rigidity, durability, and cushioning characteristics. It is a superior alternative to Styrofoam because it is environmental friendly packaging material. Plank die-cut are custom design and made to fit your needs.

■ Material:Multiple layer of EPE foam, trimmed and then die-cut to finish.

■ Function:anti-shock, lightweight, sound-insulation, , anti-moisture, void-filling.

■ Application:To block and brace products inside of box; typically used for packaging electronic instruments, pc case, monitor, and so on.

l Key features

■ Made from 100% low density polyethylene (LDPE) – Highly flexible and perfect for surface protection, interleaving and cushioning

■ Manufactured without the use of CFC’s or HCFC’s – Helps keep the environment protected by not using ozone depleting chemicals

■ Non abrasive – Will not scratch of damage finely finished surfaces

■ Moisture repellent (closed cell construction) – Provides superior protection against water, grease and solvents (below 130°f)

■ Environmental friendly – 100% recyclable and CFC free

■ Custom sizes available – Products will fit perfectly and maintain aesthetic value.

■ Cost effective – Economical alternative for all protective packaging applications.

·

防湿パッド

概要 EPEのの下敷きは、すべての木の床のクッシ ...

·

防潮墊

發泡布,又稱為 Expanded Polyethylene (EPE),是由高科技機台 ...