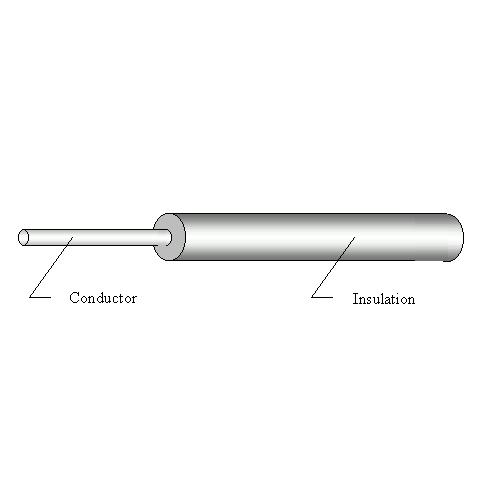

Internal wiring of electrical equipment.

Specifications

1.Conductor:Annealed Copper Wire,(Bare Single,Tinned Single, Tinned Strand,or Top-Tinned Strand) 2.Insulation: SR-PVC (Semi-Rigid Polyvinyl Chloride)3.Structure:

Conductor

Insulation

ConductorResistance(20℃)

AWG

Construction

Diameter

MinThickness

NominalThickness

Diameter

30

7 / 0.10TA

approx.0.30 mm

0.229 mm

0.25 mm

0.80 ± 0.10 mm

354.32W / Km

28

7 / 0.13TA

approx.0.39 mm

0.255 mm

0.90 ± 0.10 mm

223.75W / Km

26

7 / 0.16TA

approx.0.48 mm

0.245 mm

0.97 ± 0.10 mm

139.76W / Km

24

7 / 0.20TA

approx.0.60 mm

0.425 mm

1.10 ± 0.10 mm

85.95W / Km

24

11 / 0.16TA

approx.0.61 mm

0.245 mm

1.10 ± 0.10 mm

85.49W / Km

22

7 / 0.26TA

approx.0.78 mm

0.26 mm

1.30 ± 0.10 mm

54.79W / Km

22

17 / 0.16TA

approx.0.76 mm

0.27 mm

1.30 ± 0.10 mm

59.74W / Km

20

7 / 0.32TA

approx.0.96 mm

0.27 mm

1.50 ± 0.10 mm

34.12W / Km

20

21 / 0.18TA

approx.0.95 mm

0.275 mm

1.50 ± 0.10 mm

38.46W / Km

18

34 / 0.18TA

approx.1.21 mm

0.245 mm

1.70 ± 0.10 mm

24.70W / Km

18

42 / 0.16TA

approx.1.20 mm

0.25 mm

1.70 ± 0.10 mm

25.34W / Km

30

1 / 0.26TA

approx.0.26 mm

0.27 mm

0.80 ± 0.10 mm

359W / Km

28

1 / 0.32TA

approx.0.32 mm

0.265 mm

0.85 ± 0.10 mm

232W / Km

26

1 / 041TA

approx.0.41 mm

0.27 mm

0.95 ± 0.10 mm

146W / Km

24

1 / 0.51TA

approx.0.51 mm

0.27 mm

1.05 ± 0.10 mm

89.20W / Km

22

1 / 0.65TA

approx.0.65 mm

0.275 mm

1.20 ± 0.10 mm

56.30W / Km

20

1 / 0.813TA

approx.0.813 mm

0.268 mm

1.35 ± 0.10 mm

35.20W / Km

4.Characteristics:

Items

Specification

Rating

UL:80℃ 300V , CSA:80℃ 300V

Dielectric Strength

AC 1000V / min.

Insulation Resistance

Min. 5MW - Km (20℃) at DC 500V

Flame Test

UL:VW-1 CSA:FT-1

Elongation of Insulation

Min.100 ﹪

Tensile Strength of Insulation

Min.2.11Kg / mm2

Residual of Elongation after Aging

Min. 65 ﹪of original (113℃,168H)

Residual of Tensile Strength after Aging

Min. 70 ﹪of original (113℃,168H)

5.Marking:E54979 AWM 1061 80℃ 300V VW – 1 □AWG TATUNG