DELRIN® acetal homopolymer DELRIN® is a crystalline plastic which offers an excellent balance of properties that bridge the gap between metals and plastics. DELRIN® possesses high tensile strength, creep resistance and toughness. It also exhibits low moisture absorption. It is chemically resistant to hydrocarbons, solvents and neutral chemicals. These properties along with its fatigue endurance make DELRIN® ideal for many industrial applications. Good dimensional stability Low moisture absorption DELRIN® can operate in wet environments with little effect on performance or dimensions. Excellent machinability High fatigue endurance High strength and stiffness properties Superior impact and creep resistance Chemical resistance to fuels and solvents Natural grade is made from resin that is FDA, NSF and USDA compliant Good wear and abrasion properties With its low coefficient of friction and hard and resilient surface, DELRIN® is the material of choice in many wear applications. Delrin® 150 stock shapes are a homopolymer acetal manufactured using DuPont Delrin 150 Resin. It is a crystalline plastic which offers an excellent balance of properties to bridge the gap between metals and plastics. It possesses high tensile and flexural properties, along with creep resistance and toughness, while exhibiting low moisture absorption, and fatigue endurance. Properties Condition Value Test Method Comment Mechanical Modulus of elasticity (tensile test) 450,000 psi ASTM D 638 Tensile strength at yield 11,000 psi ASTM D 638 Elongation at break @ 73°F 25 % ASTM D 638 Flexural Strength @ 73°F 11,500 psi ASTM D 790 Modulus of elasticity (flexural test) @ 73°F 420,000 psi ASTM D 790 Compression strength 5,200 psi ASTM D 695 1) 1) 1% strain, injection molded Impact strength (Izod) @ 73°F 1.5 ft-lbs/in - Rockwell hardness @ 73°F M Scale (R Scale) 94 (120) ASTM D 785 Coefficient of friction Dynamic, 40 psi, 50 fpm .2 ASTM D 3702 Wear rate 40 psi, 50 fpm 55*10-10 in3-min/ft-lbs-hr ASTM D 3702 Thermal Melting temperature 347 °F ASTM D 2133 1) 1) Injection molded sample Deflection temperature @ 66 psi 336 °F ASTM D 648 Deflection temperature @ 264 psi 257 °F ASTM D 648 Service temperature Intermittent 300 °F - Service temperature Long term 185 °F 2) per UL746B Thermal expansion (CLTE) 6.8*10-5 in/in/°F ASTM D 696 Specific hear 0.35 BTU/lb-°F - Electrical Volume resistivity > 1014 Ω*cm ASTM D 257 Dielectric strength 500 V/mil ASTM D 149 Dissipation factor @ 60 Hz, 73°F .005 % ASTM D 150 Dielectric constant @ 60 Hz, 73°F, 50% RH 3.7 % ASTM D 150 Other Moisture absorption @ 24 hrs, 73°F 0.25 % ASTM D 570 Moisture absorption @ saturation, 73°F 0.90 % ASTM D 570 Flammability (UL94) UL 94 HB % 3) 3) at 1.47mm thickness injection mold This information is only to assist and advise you on current technical knowledge and is given without obligation or liability. All trade and patent rights should be observed. All rights reserved. Data obtained from extruded shapes material.

Round Teck International Company Introduction Round Teck International Company, is a manufacturer of quality litz wire, enameled wire (magnet wire) and Specialty Wire/Conductor, insulator, and a supplier of many standard connectivity products. The company has satisfied customers over the years by focusing on the quality of our product and the timeliness of our delivery. We have assembled Millions of cables over the years for the Installers, system integrators, OEMs and ODMs and End Users. All our clients are kept highly confidential, because of their status in their prospective countries. This confidentiality has enabled Round Teck to maintain and stimulate many long-term relationships with their international clients. Manufacturing at Round Teck is based on striving for the highest levels of Quality Assurance and Quality Control. Manufacturing techniques employ the use of high quality materials, and processes to ensure international competitiveness. Our employees are highly trained, and our international sales and shipping department can effectively give international clients the support they need. Our engineers are fully trained to handle all technical aspects of design, and production, and are at the disposal of our clients for technical and design support. Research and Development at Round Teck is a continuous process. Our R&D team is specially trained in all areas of development, and design. This training enables our R & D department to recognize potential problems, and to implement innovations quickly. At Round Teck our philosophy is to offer high quality service to our customers on a consistent and continuous basis.

A1.PT-061 A2.SP-01 A3.SP-03 A4.PT-040 A5.B-099 A6.PT-016 A7-C5148 A8.PT-053 A9.B-104 A10.ZAS18BMI A11.PT-015 A12.CS194 A13.B-146 A14.SP-04 A15.PT-008 A16.PT-063-L A17.CS216 A18.03B A19.B-143 A20.PT-063 A21.SP-09 A22.PT-048-1 B1.L-203 B2.L-101 B3.L-201 B4.L-202 B5.L-205 B6.L-104 B7.L-105 B8-L-206 B9.B-152 B10.L-107 B11.L-204 B12.B-140 B13.L-106 C1.B-102 C2.B-119 C3.B151 C4.B-212 C5.B-104 C6.B-101 C7.B-105 C8-B-100 C9.B-209 C10.B-201 C11.B-205 C12.B-203 C13.B-202 C15.KG8-9000 C16.B-106 C17.B-107 * C4為樣品模尚未生產

Used in any kind of furcation wire, and electric conductor of nylon juction. Easy to be printed. Item No. A0.1 B0.1 C0.2 D1 E1 F2 t0.2 Remark Y05030 5.0 5.0 3.0 33.0 65.0 98.0 1.0 2腳 ♦ Y06025 6.0 6.0 2.5 20.0 130.0 150.0 1.0 2腳 Y06030 6.0 6.0 3.0 33.0 45.0 78.0 1.0 2腳 Y06030-1 6.0 6.0 3.0 33.0 65.0 98.0 1.0 2腳 Y06035 6.0 6.0 3.5 33.0 65.0 98.0 1.0 2腳 Y06230 6.2 6.2 3.0 35.0 80.0 115.0 1.1 2腳 ♦ Y06231 6.2 6.2 3.0 35.0 110.0 145.0 1.0 2腳 Y07035 7.0 7.0 3.5 33.0 65.0 98.0 1.0 2腳 ♦ Y07036 7.0 7.0 3.5 33.0 110.0 143.0 1.0 2腳 Y07038 7.0 7.0 3.8 23.0 36.0 59.0 1.0 2腳 Y07040 7.0 7.0 4.0 40.0 20.0 60.0 1.0 2腳 ♦ Y07041 7.0 7.0 4.0 40.0 70.0 110.0 1.0 2腳 ♦ Y07045 7.0 7.0 4.5x6.5 31.5 55.0 86.0 1.0 2腳 Y07238 7.2 7.2 3.8 22.0 29.0 51.0 1.0 2腳 ♦ Y07525 7.5 7.5 2.5 30.0 50.0 80.0 1.0 2腳 ♦ Y07526 7.5 7.5 2.5 30.0 110.0 140.0 1.0 2腳 ♦ Y07529 7.5 7.5 2.9 40.0 65.0 105.0 1.0 2腳 ♦ Y07540 7.5 7.5 4.0 20.0 37.0 57.0 1.0 2腳 ♦ Y07745 7.7 7.7 4.5 60.0 95.0 155.0 1.2 2腳 Y08032 8.0 8.0 3.2 38.0 70.0 108.0 1.0 2腳 ♦ Y08035 8.0 8.0 3.5 40.0 115.0 155.0 1.0 2腳 ♦ Y08055 8.0 8.0 5.5 30.0 70.0 100.0 1.0 2腳 ♦ Y08057 8.0 8.0 6.0x3.0 53.0 107.0 160.0 1.0 2腳 Y08532 8.5 8.5 3.2 35.0 45.0 80.0 1.0 2腳 Y08532-1 8.5 8.5 3.2 35.0 70.0 105.0 1.2 2腳 ♦ Y08535 8.5 8.5 3.5 41.0 115.0 156.0 1.1 2腳 Y08537 8.5 8.5 3.7 38.0 64.0 102.0 1.0 2腳 ♦ Y08538 8.5 8.5 3.7 38.0 110.0 148.0 1.0 2腳 ♦ Y08545 8.5 8.5 4.5 35.0 70.0 105.0 1.0 2腳 ♦ Y08546 8.5 8.5 4.5 35.0 110.0 145.0 1.0 2腳 ♦ Y09030 9.0 9.0 3.0 20.0 145.0 165.0 1.0 2腳 Y09032 9.0 9.0 3.2 38.0 100.0 138.0 1.0 2腳 ♦ Y09035 9.0 9.0 3.5 40.0 115.0 155.0 1.0 2腳 Y09040 9.0 9.0 4.0 38.0 40.0 78.0 1.0 2腳 ♦ Y09042 9.0 9.0 4.0 50.0 115.0 165.0 1.2 2腳 ♦ Y09252 9.2 9.2 5.2 40.0 110.0 150.0 1.0 2腳 Y09335 9.3 9.3 3.5 28.0 47.0 75.0 1.0 2腳 ♦ Y09532 9.5 9.5 3.2 38.0 100.0 138.0 1.0 2腳 ♦ Y09544 9.5 9.5 4.4 25.0 50.0 75.0 1.0 2腳 Y10032 10.0 8.0 3.2 28.0 34.0 62.0 1.0 2腳 Y10040 10.0 10.0 4.0 38.0 60.0 98.0 1.1 2腳 ♦ Y10070 10.0 10.0 7.0 30.0 70.0 100.0 1.0 2腳 Y10548 10.5 10.5 4.8 35.0 53.0 88.0 1.1 2腳 Y10573 10.5 10.5 7.3 28.0 25.0 53.0 1.1 2腳 Y11048 11.0 11.0 4.8 35.0 55.0 90.0 1.1 2腳 ♦ Y11050 11.0 11.0 5.0 25.0 50.0 75.0 1.0 2腳 ♦ Y11055 11.0 11.0 5.5 45.0 120.0 165.0 1.2 2腳 Y11065 11.0 11.0 6.5 42.0 56.0 98.0 1.1 2腳 Y11435 11.4 11.4 3.5 29.0 42.0 71.0 1.0 2腳 ♦ Y11570 11.5 11.5 7.0 30.0 25.0 55.0 1.0 2腳 Y12048 12.0 12.0 4.8 40.0 80.0 120.0 1.1 2腳 ♦ Y12065 12.0 12.0 6.5 40.0 56.0 96.0 1.0 2腳 ♦ Y12565 12.5 12.5 6.5 50.0 115.0 165.0 1.2 2腳 ♦ Y13045 13.0 13.0 4.5 40.0 60.0 100.0 1.0 2腳 Y14048 14.0 10.5 4.8 40.0 58.0 96.0 1.0 2腳 ♦ Y14061 14.0 14.0 6.0 40.0 120.0 160.0 1.2 2腳 ♦ Y14062 18.0 10.0 6.0 50.0 115.0 165.0 1.2 2腳 Y14060 14.0 14.0 6.0 40.0 60.0 100.0 1.0 2腳 Y14510 14.5 14.5 10.2×5.2 50.0 90.0 140.0 1.3 2腳 ♦ Y14568 14.5 14.5 6.8 60.0 100.0 160.0 1.2 2腳 Y15060 15.0 15.0 6.0 40.0 66.0 100.0 1.0 2腳 ♦ Y15061 15.0 15.0 6.0 50.0 100.0 150.0 1.2 2腳 Y15070 15.0 15.0 7.0 40.0 60.0 100.0 1.3 2腳 ♦ Y15084 15.0 15.0 8.4 40.0 30.0 70.0 1.2 2腳 ♦ Y16060 16.0 16.0 6.0 40.0 100.0 140.0 1.2 2腳 ♦ Y16061 16.0 16.0 6.0 50.0 115.0 165.0 1.2 2腳 Y17060 17.0 17.0 6.0 40.0 63.0 103.0 1.2 2腳 ♦ Y17085 17.0 17.0 11.0x6.0 50.0 100.0 150.0 1.0 2腳 Y18060 18.0 14.0 6.0 42.0 60.0 102.0 1.2 2腳 Y19060 19.0 19.0 6.0 45.0 70.0 115.0 1.2 2腳 Y19065 19.0 19.0 6.5 45.0 66.0 111.0 1.3 2腳 ♦ Y19066 19.0 19.0 6.0 38.0 100.0 138.0 1.2 2腳 ♦ Y19067 19.0 19.0 6.0 40.0 120.0 160.0 1.2 2腳 Y19075 19.0 19.0 7.5 45.0 65.0 110.0 1.3 2腳 ♦ Y21080 21.0 21.0 8.0 40.0 10.0 50.0 1.0 2腳 ♦ Y22075 22.0 22.0 7.5 45.0 120.0 165.0 1.5 2腳 ♦ Y101060 10.1 10.1 6.0 30.0 25.0 55.0 1.0 2腳 ♦ Y135083 13.5 13.5 10.0x6.5 40.0 70.0 110.0 1.3 2腳 ♦ Y138045 13.8 13.8 4.5 40.0 85.0 125.0 1.0 2腳 ♦ Y154050 15.4 15.4 5.0 40.0 85.0 125.0 1.0 2腳 ♦ Y173050 17.3 17.3 5.0 75.0 90.0 110.0 1.2 2腳 Standard Colors:Black, Red, Blue .....etc. ♦The specification developed recently , has not applied for UL authentication yet. Used in any kind of furcation wire, and electric conductor of nylon juction. Easy to be printed. Item No. A0.1 B0.1 C0.2 D1 E1 F2 t0.2 Remark PT309040 9.5 9.5 4.0 45.0 75.0 120.0 1.0 3腳 ♦ PT310038 10.0 10.0 3.8 ,2.5 57.0 57.0 114.0 1.0 3腳 ♦ PT3065035 6.5 6.5 3.5 45.0 80.0 125.0 1.2 3腳 ♦ PT3124055 12.4 12.4 5.5 40.0 125.0 165.0 1.2 3腳 ♦ PT3138052 13.8 13.8 5.2 30.0 25.0 55.0 1.0 3腳 PT3138052 14.0 14.0 5.4 30.0 25.0 55.0 1.0 3腳 ♦ PT3142055 14.2 14.2 5.5 50.0 80.0 130.0 1.1 3腳 Item No. A0.1 B0.1 C0.2 D1 E1 F2 t0.2 Remark PT4-075 11.0 11.0 4.0 29.0 116.0 145.0 1.2 4腳 PT4-077 16.2 16.2 5.25 46.0 108.0 154.0 1.3 4腳 PT4-078 18.0 18.0 6.5 40.0 110.0 150.0 1.3 4腳 PT4-084 9.5 9.5 4.0 45.0 115.0 160.0 1.2 4腳 PT4-085 9.5 9.5 4.0 40.0 20.0 60.0 1.0 4腳 PT4-087 22.0 22.0 9.0 40.0 119.0 159.0 1.4 4腳 PT4-090 8.5 8.5 3.7 45.0 112.0 157.0 1.2 4腳 PT4-091 8.0 8.0 3.0 44.0 116.0 160.0 1.0 4腳 PT4-094 8.6 8.6 3.0 46.0 100.0 146.0 1.0 4腳 PT4-095 9.0 9.0 2.0 20.0 81.0 126.0 1.2 4腳 ♦ PT4-096 8.5 8.5 3.7 45.0 140.0 160.0 0.9 4腳 PT4-097 14.5 14.5 5.2 50.0 90.0 140.0 1.2 4腳 ♦ PT4-099 11.5 11.5 4.0 30.0 25.0 55.0 1.0 4腳 PT4-100 6.8 6.8 3.0 35.0 85.0 120.0 1.0 4腳 ♦ PT4-101 8.0 8.0 2.0 44.0 116.0 160.0 1.0 4腳 ♦ PT4-102 12.7 12.7 4.5 30.0 30.0 60.0 1.0 4腳 ♦ PT4-103 12.0 12.0 4.8 40.0 85.0 125.0 1.2 4腳 ♦ PT4-104 13.8 13.8 4.5 40.0 85.0 125.0 1.0 4腳 ♦ PT4-105 22.0 22.0 7.5 45.0 120.0 165.0 1.5 4腳 ♦ PT4-106 10.1 10.1 3.2 30.0 25.0 55.0 1.0 4腳 ♦ PT4-107 17.0 17.0 6.0 50.0 100.0 150.0 1.2 4腳 ♦ PT4-109 8.6 8.6 3.0 30.0 135.0 165.0 1.2 4腳 ♦ PT4-110 9.5 9.5 3.2 44.0 106.0 150.0 1.0 4腳 ♦ PT4-111 15.0 15.0 5.0 40.0 30.0 70.0 1.2 4腳 ♦ PT4-112 7.5 7.5 3.5 25.0 65.0 90.0 1.0 4腳 ♦ PT4-113 8.0 8.0 3.0 44.0 153.0 197.0 1.3 4腳 ♦ PT4-114 14.5 14.5 5.0 60.0 100.0 160.0 1.2 4腳 Item No. A0.1 B0.1 C0.2 D1 E1 F2 t0.2 Remark ♦PT5-001 16.5 16.5 5.2 30.0 25.0 55.0 1.0 5腳 Item No. A0.1 B0.1 C0.2 D1 E1 F2 t0.2 Remark ♦ PT6-090 9.0 9.0 3.0 30.0 135.0 165.0 1.2 6腳 PT6-092 9.0 9.0 3.0 44.0 116.0 160.0 1.0 6腳 Standard Colors:Black, Red, Blue or other ♦The specification developed recently , has not applied for UL authentication yet.

Insulating cover for electronic sections, wire, cable and special tube's terminal to prevent damp and dast. Item No. d L1 t0.2 Packing unit VCP-1.7 1.7 16.0 0.8 2000 pcs VCP-2.0 2.0 12.0 0.8 2000 pcs ♦ VCP-2.5 2.5 7.0 0.8 2000 pcs VCP-2.6 2.6 9.0 0.8 2000 pcs VCP-2.9 2.9 13.0 1.0 2000 pcs VCP-3.2 3.2 13.0 1.0 2000 pcs ♦ VCP-3.5 3.5 13.0 1.0 1000 pcs VCP-4.0 4.0 8.0 1.0 1000 pcs VCP-4.5 4.5 13.0 1.0 1000 pcs VCP-4.8 4.8 13.0 1.0 1000 pcs VCP-5.2 5.2 15.0 1.0 1000 pcs VCP-5.7 5.7 13.0 1.0 1000 pcs VCP-6.0 6.0 12.0 1.0 1000 pcs VCP-6.5 6.5 13.0 1.0 1000 pcs VCP-7.0 7.0 13.0 1.0 1000 pcs VCP-7.4 7.4 15.0 1.0 1000 pcs VCP-7.6 7.6 8.0 1.0 1000 pcs VCP-8.0 8.0 10.0 1.0 1000 pcs VCP-8.2 8.2 13.0 1.0 1000 pcs VCP-8.5 8.5 9.0 1.0 1000 pcs ♦ VCP-9.0 9.0 13.0 1.0 1000 pcs VCP-9.2 9.2 11.0 1.0 1000 pcs VCP-9.5 9.4 16.0 1.0 1000 pcs VCP-10 10.0 20.0 1.0 1000 pcs VCP-11 11.0 23.0 1.3 1000 pcs ♦ VCP-11.4 11.4 20.0 1.2 1000 pcs VCP-11.7 11.7 10.0 1.5 1000 pcs VCP-12 12.0 16.0 1.0 500 pcs ♦ VCP-13 13.0 15.0 1.2 500 pcs VCP-14 14.0 35.0 1.3 500 pcs VCP-15 15.0 14.0 1.3 500 pcs VCP-15.5 15.5 20.0 1.3 500 pcs ♦ VCP-16 16.0 20.0 1.3 500 pcs VCP-17 17.0 13.0 1.3 500 pcs VCP-18 17.8 13.0 1.3 500 pcs ♦ VCP-19 17.8 13.0 1.3 500 pcs VCP-20.5 20.5 20.0 1.3 200 pcs ♦ VCP-21 21.0 16.0 1.5 200 pcs VCP-22 22.0 16.0 1.3 200 pcs ♦ VCP-23 23.0 25.0 1.5 200 pcs ♦ VCP-24 24.0 25.0 1.6 200 pcs ♦ VCP-25.4 25.4 25.0 1.5 200 pcs VCP-26 26.0 50.0 1.5 200 pcs ♦ VCP-26.7 26.7 15.0 1.5 200 pcs VCP-26.8 26.8 58.0 1.8 200 pcs ♦ VCP-27.1 27.1 58.0 1.8 100 pcs ♦ VCP-28 28.0 15.0 1.5 500 pcs ♦ VCP-30 30.0 20.0 1.6 500 pcs ♦ VCP-31.5 31.5 20.0 1.5 200 pcs VCP-33 33.0 25.0 1.6 200 pcs ♦ VCP-33.6 33.6 15.0 1.5 200 pcs ♦ VCP-35 35.0 20.0 1.6 200 pcs ♦ VCP-37.8 37.8 45.0 1.6 100 pcs ♦ VCP-40 40.0 60.0 1.6 100 pcs ♦ VCP-40.7 40.7 15.0 1.5 100 pcs ♦ VCP-47 47.0 22.0 2.0 100 pcs ♦ VCP-50 50.0 20.0 1.8 100 pcs VCP-52 52.0 95.0 1.8 50 pcs ♦ VCP-53.6 53.6 13.0 1.7 200 pcs ♦ VCP-58 58.0 30.0 1.8 100 pcs ♦ VCP-60 60.0 20.0 1.8 100 pcs ♦ VCP-65.8 65.8 15.0 1.6 100 pcs ♦ VCP-76 76.0 37.0 2.0 50 pcs ♦ VCP-80 80.0 45.0 1.8 25 pcs ♦ VCP-105 105.0 63.0 2.0 25 pcs Section L and t dimensions according to customers' specification Standard colors: red, black, yellow, green, blue, white ♦The specification developed recently , has not applied for UL authentication yet.

Used in rounded crimping terminal exposed part of minitype wire. There are six Kinds of color to be used in twenty three dimensions of wire. Item No. Applicable wires d1 d2 1 L2 t0.2 Packing unit V-1.25 1.25 mm2 3.3 3.1 7.0 8.0 15.0 0.6 100 pcs V-2.0 2.0 mm2 4.5 3.7 8.0 8.0 16.0 0.7 100 pcs V-3.5 3.5 mm2 5.7 4.1 9.0 9.0 18.0 0.8 100 pcs V-5.5 5.5 mm2 5.7 5.2 10.0 10.0 20.0 0.8 100 pcs V-8.0 8.0 mm2 7.2 6.2 11.0 10.0 21.0 1.0 100 pcs ♦ V-10 8.0 mm2 8.5 6.6 13.5 13.0 26.0 1.0 100 pcs V-12 12 mm2 10.0 7.3 13.0 14.0 27.0 1.1 100 pcs V-14 14 mm2 10.0 8.0 15.0 13.0 28.0 1.1 100 pcs V-22 22 mm2 12.0 9.5 15.0 14.0 29.0 1.2 100 pcs V-38 38 mm2 14.0 11.8 17.0 17.0 34.0 1.4 100 pcs V-60 60 mm2 17.0 13.9 22.0 20.0 42.0 1.5 100 pcs V-70 70 mm2 17.9 15.1 25.5 19.0 45.0 1.5 100 pcs V-80 80 mm2 19.0 16.0 25.0 21.0 46.0 1.5 50 pcs V-100 100 mm2 22.0 18.0 31.0 24.0 55.0 1.7 50 pcs V-125 125 mm2 24.0 20.0 32.0 28.0 60.0 1.8 50 pcs V-150 150 mm2 26.0 22.0 34.0 31.0 65.0 1.8 50 pcs V-185 185 mm2 29.0 24.0 33.0 33.4 66.7 1.8 50 pcs V-200 200 mm2 32.2 24.0 38.0 31.0 69.0 2.0 50 pcs V-250 250 mm2 36.5 27.2 42.0 33.0 75.0 2.0 50 pcs V-325 325 mm2 36.7 30.0 42.0 33.0 75.0 2.0 25 pcs V-400 400 mm2 45.1 37.5 43.0 40.0 83.0 2.0 25 pcs V-500 500 mm2 48.2 40.2 43.0 42.0 85.0 2.0 25 pcs V-630 630 mm2 53.8 45.2 48.0 45.0 93.0 2.0 25 pcs Stander colors: red, white, blue, black, yellow, green♦The specification developed recently , has not applied for UL authentication yet.

Available to fix, water-proof and dust-proof for lamp socket switch, wiring, and bundle. Item No. d D A L2 t0.2 Packing unit ♦ C1201 3.6 10.0 1.5 12.0 30.5 1.0 1000 pcs ♦ C1202 2.6 9.0 7.5 8.5 27.0 1.0 1000 pcs ♦ C1204 4.0 11.8 10.0 15.0 26.0 1.0 1000 pcs ♦ C1603 3.8 15.7 14.5 16.5 31.0 1.0 500 pcs ♦ C1604 3.8 15.7 14.0 16.2 31.0 1.0 500 pcs ♦ C1605 3.8 15.7 10.5 16.5 31.0 1.0 1000 pcs ♦ C1606 2.5 12.0 4.0 4.5 21.5 1.2 1000 pcs C4001 8.8 12.0 19.5 19.0 40.0 1.2 500 pcs C4002 4.6 12.0 22.0 16.5 43.0 1.2 500 pcs C4003 4.6 14.0 21.5 20.5 47.0 1.2 500 pcs C4005 6.5 15.0 19.0 20.5 45.0 1.2 500 pcs ♦ C4006 9.0 14.0 11.0 16.0 30.0 1.0 500 pcs ♦ C4008 9.0 12.0 13.0 24.0 38.0 1.5 500 pcs ♦ C4011 4.8 16.0 18.0 17.0 42.0 1.1 500 pcs ♦ C4013 8.8 24.0 19.0 28.0 53.0 1.2 200 pcs ♦ C4016 7.0 15.0 10.0 10.0 25.5 1.3 500 pcs ♦ C4018 7.0 18.0 18.0 48.0 70.0 1.2 200 pcs ♦ C4019 8.0 19.0 4.0 21.0 43.0 1.3 200 pcs ♦ C4020 10.5 20.8 4.0 23.0 43.0 1.3 200 pcs ♦ C4023 5.6 7.3 12.0 13.0 27.0 1.2 1000 pcs ♦ C4027 4.7 11.2 11.5 13.0 28.0 1.2 1000 pcs ♦ C4028 5.1 12.7 20.0 21.0 47.0 1.2 500 pcs ♦ C4029 6.9 12.0 15.0 30.0 47.0 1.3 500 pcs ♦ C4031 5.0 8.0 4.0 24.0 33.0 1.3 1000 pcs ♦ C4032 5.6 12.7 17.0 34.0 58.0 1.3 500 pcs ♦ C4033 7.0 9.0 18.0 26.0 45.0 1.8 500 pcs ♦ C4034 4.2 9.5 15.5 18.5 35.0 1.0 1000 pcs ♦ C4036 9.8 12.5 7.0 11.5 21.0 1.5 1000 pcs ♦ C4039 3.8 6.0 11.0 13.5 27.0 1.0 1000 pcs ♦ C4040 4.5 6.0 11.0 15.0 28.0 1.0 1000 pcs ♦ C4042 7.1 14.0 14.0 48.0 67.0 1.2 200 pcs ♦ C4045 5.7 12.7 12.7 36.0 68.0 1.1 500 pcs ♦ C4048 7.0 10.5 12.0 43.0 53.0 1.2 500 pcs ♦ C4052 6.2 11.5 10.0 25.0 40.0 1.0 500 pcs ♦ C4053 6.3 12.0 5.5 60.0 65.0 1.2 200 pcs ♦ C4055 3.2 11.0 13.0 19.0 35.0 1.3 1000 pcs ♦The specification developed recently , has not applied for UL authentication yet. C5101 12.0 28.0 22.0 43.0 75.0 1.3 100 pcs C5102 12.0 22.0 23.0 40.0 73.0 1.3 200 pcs C5103 12.0 35.0 11.0 52.0 68.0 1.0 100 pcs C5104 17.5 28.5 35.0 40.0 85.0 1.5 100 pcs C5105 11.0 38.0 12.0 21.0 38.0 1.2 200 pcs C5106 20.0 38.0 14.0 55.0 80.0 1.2 100 pcs C5107 17.0 38.0 15.0 69.0 90.0 1.4 50 pcs C5108 16.0 43.0 15.0 81.0 100.0 1.5 200 pcs C5109 7.5 15.0 12.0 49.0 66.0 1.2 100 pcs C5110 15.0 25.0 20.0 60.0 90.0 1.2 200 pcs C5111 8.0 22.0 18.0 39.0 65.0 1.2 100 pcs C5112 12.3 31.8 21.2 50.6 80.0 1.5 50 pcs C5114 22.0 65.0 12.0 70.0 100.0 1.5 50 pcs C5115 20.0 50.0 20.0 70.0 100.0 1.5 50 pcs C5116 6.5 9.5 12.0 17.0 32.5 1.2 1000 pcs C5117 2.0 16.3 4.5 7.0 15.5 1.2 1000 pcs C5119 8.5 21.0 19.5 24.0 47.0 1.2 200 pcs C5121 5.6 37.5 4.0 49.0 58.0 1.4 100 pcs C5125 19.0 54.0 18.0 70.0 100.0 1.3 50 pcs C5126 3.5 23.0 5.0 45.0 54.0 1.5 200 pcs C5131 4.8 6.0 11.3 12.7 26.0 1.2 1000 pcs C5132 5.0 8.0 10.0 17.5 29.0 1.0 1000 pcs C5134 5.0 12.0 11.0 19.0 32.0 1.2 1000 pcs C5135 6.0 7.0 12.0 13.0 26.0 1.0 1000 pcs C5138 4.0 5.0 14.0 5.5 20.0 1.0 1000 pcs C5139 11.0 39.5 12.0 25.0 42.0 1.4 100 pcs C5141 21.0 25.0 17.5 46.0 65.0 1.5 1000 pcs C5142 3.5 9.0 18.0 19.0 39.0 1.0 1000 pcs C5144 4.7 9.0 6.5 12.5 21.5 1.2 1000 pcs C5145 6.7 11.0 14.5 15.0 31.0 1.2 1000 pcs C5146 7.6 11.4 20.0 20.0 50.0 1.2 500 pcs C5148 5.0 16.0 14.0 22.5 45.5 1.2 500 pcs C5150 9.0 34.0 18.0 18.5 43.5 1.3 200 pcs C5151 8.0 26.0 14.0 14.0 39.0 1.3 200 pcs Section A and t dimensions according to customers' specification Standard colors: Black

This protective casing is suitable used for small-sized multi-pole nylon connection cable and various computer PC boards, etc. to prevent dust entering into inlet part of the cable for protection and insulation. It also function to prevent falling off the wire cable easily, etc.As this protection casing is made of excellent soft quality of P.V.C, it is very suitably used for connection wire and cable bundle. Item No. A B C D d L2 t 0.2 Packing unit CS090 9.0 7.3 13.0 2.0 2.7 23.0 1.0 1000 pcs CS130 13.0 6.0 13.0 8.0 6.0 47.0 1.3 500 pcs CS131 13.0 13.0 24.0 10.0 5.0 51.0 1.1 500 pcs ♦ CS138 13.8 13.8 14.5 5.0 7.7 48.5 1.1 500 pcs ♦ CS140 14.0 8.5 18.0 5.0 5.0 29.0 1.3 500 pcs CS146 14.5 12.0 25.0 6.0 11.0 51.0 1.2 500 pcs ♦ CS148 14.8 6.3 13.0 9.0 6.3 46.0 1.0 500 pcs CS156 15.6 6.5 16.5 14.5 6.1 45.0 1.2 500 pcs CS160 16.0 16.0 26.0 10.0 8.0 62.0 1.2 200 pcs ♦ CS168 16.8 6.3 17.0 5.0 6.3 52.0 1.0 500 pcs ♦ CS169 16.8 6.5 16.0 4.5 9.1 54.0 1.0 200 pcs CS170 17.0 17.0 31.0 7.0 9.0 65.0 1.2 200 pcs CS174 17.0 4.8 7.5 3.5 2.7 15.0 0.8 200 pcs CS175 17.5 17.5 36.0 8.0 6.3 56.0 1.2 200 pcs CS190 19.0 13.0 15.0 14.0 10.0 64.0 1.5 200 pcs CS192 19.2 11.2 12.5 8.0 4.9 41.0 1.2 200 pcs CS194 19.4 7.6 17.6 7.4 10.3 40.0 1.2 200 pcs CS200 20.0 5.5 15.0 4.0 12.0 44.0 1.2 200 pcs CS210 21.0 18.0 26.0 14.0 8.0 55.0 1.2 200 pcs CS211 21.0 14.5 31.0 13.0 5.5 70.0 1.0 200 pcs CS214 21.5 16.0 22.0 5.0 4.1 43.0 1.2 500 pcs CS216 21.6 7.6 18.6 11.4 6.4 50.0 1.2 200 pcs CS220 22.0 22.0 47.0 8.5 11.6 75.0 1.5 200 pcs CS221 22.0 18.5 48.0 10.0 8.0 73.0 1.2 200 pcs CS223 22.0 16.0 20.0 7.0 12.0 47.0 1.2 200 pcs CS225 22.5 11.0 16.0 21.0 6.0 44.0 1.1 200 pcs CS226 22.0 6.0 16.0 6.0 7.2 48.0 1.1 500 pcs ♦ CS228 22.0 18.5 48.0 10.0 8.0 80.0 1.2 200 pcs ♦ CS230 23.0 10.0 15.0 9.5 8.0 44.0 1.2 200 pcs ♦ CS231 23.0 15.0 17.0 3.0 11.0 52.0 1.5 200 pcs ♦ CS245 24.5 19.0 35.0 10.0 10.0 75.0 1.2 200 pcs ♦ CS250 24.5 18.0 25.0 6.0 6.0 45.5 1.8 200 pcs CS253 25.3 19.1 30.0 14.0 7.0 49.0 1.7 200 pcs ♦ CS254 25.4 19.0 14.0 25.0 8.0 60.0 1.5 200 pcs ♦ CS255 25.5 2.6 2.0 20.0 5.2 50.0 1.2 500 pcs CS256 25.0 7.5 6.0 22.5 6.0 40.0 1.5 500 pcs ♦ CS270 27.0 11.0 29.0 24.0 6.0 67.0 1.4 200 pcs ♦ CS275 27.5 22.0 52.0 5.0 8.0 80.0 2.0 100 pcs ♦ CS276 27.5 22.0 52.0 5.0 11.0 80.0 2.0 100 pcs CS278 27.2 8.9 20.0 20.0 8.0 50.0 1.2 200 pcs ♦ CS279 27.8 12.0 14.0 10.0 17.0 35.0 1.2 200 pcs CS280 28.0 27.0 30.0 13.0 11.0 60.0 1.2 200 pcs CS290 29.5 13.5 15.0 13.0 10.5 62.0 1.5 200 pcs ♦ CS291 29.0 13.0 18.0 13.0 13.0 62.0 1.5 200 pcs CS292 29.0 22.0 38.0 7.0 13.0 75.0 1.2 100 pcs CS295 29.5 14.0 14.0 14.0 11.0 64.0 1.2 200 pcs ♦ CS296 29.0 26.0 45.0 5.5 7.2 68.0 1.8 100 pcs CS297 29.0 7.8 21 3.0 7.2 39.0 1.2 500 pcs CS300 30.0 15.0 38.0 7.0 9.0 70.0 1.2 200 pcs ♦ CS301 30.0 10.9 30.0 15.5 8.0 62.0 1.3 200 pcs CS302 30.0 22.0 25.0 10.0 9.0 55.0 1.2 200 pcs CS322 32.0 24.0 35.0 10.0 9.0 65.0 1.2 100 pcs CS323 32.0 30.0 35.0 16.0 11.5 71.0 1.2 100 pcs ♦ CS329 32.0 27.0 36.0 7.0 6.0 58.0 1.5 100 pcs ♦ CS330 33.0 11.0 30.0 17.5 7.0 50.0 1.3 200 pcs CS335 33.5 22.0 38.0 7.0 9.0 75.0 1.0 100 pcs ♦ CS340 34.0 22.0 31.0 14.0 9.7 65.0 1.2 100 pcs CS344 34.5 22.5 23.0 9.0 4.0 47.0 1.5 200 pcs ♦ CS350 35.0 19.0 42.0 17.0 9.5 79.0 1.5 100 pcs ♦ CS351 35.0 16.0 29.0 12.0 12.0 63.0 1.5 200 pcs CS355 35.5 19.5 42.0 15.5 9.0 72.0 1.5 100 pcs CS380 38.0 13.7 15.0 15.0 13.0 65.0 1.5 200 pcs CS385 38.0 28.5 35.0 10.0 5.0 58.0 1.0 200 pcs ♦ CS386 38.0 6.0 7.0 23.0 15.8 42.0 1.2 200 pcs CS400 39.0 29.0 20.0 20.0 10.0 64.0 1.0 100 pcs CS420 42.0 22.0 44.0 8.0 13.0 81.0 1.4 100 pcs ♦ CS430 43.0 1.5 48.0 14.0 10.3 67.0 1.5 200 pcs ♦ CS450 45.0 24.5 75.0 5.0 9.0 105.0 1.6 50 pcs ♦ CS465 46.5 9.5 27.0 18.0 7.5x12.0 46.0 1.6 200 pcs CS500 51.0 25.4 30.0 10.0 16.0 65.0 1.0 100 pcs CS510 51.0 2.0 27.0 23.0 11.0 69.0 1.5 100 pcs ♦ CS540 54.0 17.0 20.0 9.0 13.0 45.0 1.3 100 pcs ♦ CS541 54.0 21.0 31.0 8.5 11.5 65.5 1.0 100 pcs ♦ CS720 71.7 27.6 30.0 13.5 7.0 60.0 1.6 100 pcs Section C and t dimensions according to customers' specification Standard colors: Black ♦The specification developed recently , has not applied for UL authentication yet.

Item No. d D L2 t0.2 Packing unit 01A 3.1 5.6 34.0 0.8 500 pcs ♦ 01B 2.5 5.5 30.0 1.0 500 pcs ♦ 01C 2.7 5.5 32.0 1.0 500 pcs 02A 3.3 6.1 40.0 0.8 500 pcs ♦ 02B 3.7 6.5 42.0 1.1 500 pcs 03A 3.6 8.1 54.0 1.0 500 pcs 03A (H) 3.6 8.3 50.0 1.0 500 pcs ♦ 03E 4.2 8.2 54.0 1.0 500 pcs 04A 5.5 7.5 38.0 1.1 500 pcs Standar colors:red,black,yellow,green,blue,white. ♦The specification developed recently , has not applied for UL authentication yet. 05A 3.5 11.0 55.0 1.2 500 pcs ♦ 05B 3.8 11.8 53.0 1.1 500 pcs 10A 4.0 14.3 64.0 1.2 200 pcs 20A 5.5 14.0 68.0 1.2 200 pcs 20B 5.1 15.0 75.0 1.2 200 pcs 20B(N) 6.9 15.0 75.0 1.2 200 pcs ♦ 20C 5.1 15.0 88.0 1.2 200 pcs 25A 6.5 25.5 88.0 2.0 100 pcs Item No. d A B L2 t0.2 Packing unit 20A-SQ 5.1 14.0 12.0 77.0 1.2 200 pcs ♦ 25A-SQ 4.5 12.5 15.8 82.5 1.4 200 pcs 50A-SQ 8.5 27.0 19.0 120.0 1.8 100 pcs ♦The specification developed recently , has not applied for UL authentication yet.

Capacitor Cover (type 1) Item No. A B C1.0 D E t0.2 Packing unit HU-8 8.5 7.5 11.0 3.0 4.0 1.0 1000 pcs HU-10 10.5 9.0 13.0 3.0 4.0 1.0 1000 pcs HU-11 11.5 9.5 13.0 4.0 4.5 1.0 500 pcs HU-12 12.0 10.0 15.0 3.8 7.8 1.0 500 pcs * HU-13 13.0 11.5 18.0 3.8 4.8 1.0 500 pcs * HU-14 14.0 12.0 16.0 3.0 4.0 1.0 500 pcs * HU-16 16.0 13.0 19.0 3.5 4.5 1.0 500 pcs HU-17 15.8 13.6 19.0 4.8 6.2 1.0 500 pcs *Planning to create Capacitor Cover (type 2) Item No. A d1 P 0.5 L1 W1 W2 t0.2 H-12 12.0 1.5 6.5 13.0 6.0 19.0 9.6 5.0 1.0 H-14 14.0 2.0 9.0 16.0 6.0 22.0 12.0 4.0 1.0 H-16 16.0 2.0 6.0 20.0 13.0 33.0 12.0 7.0 1.0 * H-18 18.0 2.0 10.0 21.0 15.0 36.0 14.0 7.0 1.0 ♦ H-19 18.5 1.5 15.0 11.0 15.0 26.0 18.5 5.5 1.0 *Planning to create Packing unit: 1,000 pcs per bag ♦The specification developed recently , has not applied for UL authentication yet. Fuse Cover Item No. L10.3 L21.0 L30.2 L1 A t0.2 Packing unit FH-1 6.0 11.5 20.0 12.5 1.0 1.2 1000 pcs FH-1L 6.0 11.5 22.0 12.5 1.0 1.2 1000 pcs FH-1S 5.3 11.0 18.0 12.5 1.0 1.2 1000 pcs FH-2 6.1 11.0 20.3 12.0 1.5 1.2 1000 pcs FH-3 9.5 13.0 31.8 14.5 1.5 1.30.3 500 pcs FH-3A 9.1 11.5 31.8 12.5 1.0 1.2 500 pcs FH-4 12.8 19.0 41.0 20.5 1.5 1.2 500 pcs FH-5 8.0 10.0 36.0 11.0 1.0 1.2 500 pcs FH-11 6.2 16.0 16.0 17.0 1.0 1.1 1000 pcs FH-12 5.0 18.0 15.0 19.0 1.0 1.0 1000 pcs FH-13 4.7 9.0 12.2 10.0 1.0 1.0 1000 pcs FH-15 6.1 20.5 18.0 21.5 1.0 1.0 1000 pcs FH-16 7.0 23.5 24.3 24.5 1.0 1.0 1000 pcs ♦ FH-17 10.6 12.5 16.3 15.0 2.5 1.3 1000 pcs ♦ FH-21 9.5 8.0 13.8 10.0 2.0 1.0 1000 pcs ♦The specification developed recently , has not applied for UL authentication yet.

Conventional flag type sleeves Item No. d L11.0 L21.0 W1 W2 t0.2 Remark F6230 3.0 12.0 13.0 6.2 3.0 1.0 187 type * F8040 4.0 14.0 15.0 8.0 3.5 1.0 205 type * F8845 4.5 13.0 15.0 8.8 3.5 1.0 250 type F8532 3.2 16.4 17.5 8.4 3.2 1.0 250 type F8540 4.0 18.0 18.0 9.5 4.0 1.0 250 type F8550 5.0 18.0 18.0 9.2 4.4 1.0 250 type * Please refer to the picture(II) Post Insertion Flag type sleeves Item No. d L11.0 L21.0 W1 W2 t0.2 H * F110 2.8 12.0 14.0 4.0 2.8 1.0 1.0 F187 3.0 12.0 13.0 6.4 3.0 1.0 1.0 F205 3.3 13.0 14.0 7.0 3.0 1.0 1.0 F250/16 4.0 13.0 16.0 8.2 4.0 1.0 1.0 F250/18 4.0 16.0 18.0 9.0 4.0 1.0 1.0 *2000 pcs per bag Packing unit: 1,000 pcs per bag

Shur Plug type sleeves (male) Item No. L1.5 t0.2 R4225 2.5 3.8 5.0 2.5 4.5 14.0 1.0 R4228 2.7 3.7 5.0 2.8 4.5 15.0 1.0 R4230 3.0 4.1 5.2 2.8 4.5 15.0 1.0 R4235 3.5 4.4 5.3 3.0 4.5 16.0 1.0 R4240 4.0 4.7 5.5 3.0 4.5 14.5 1.0 R3528 2.8 3.3 3.8 3.0 4.5 14.0 1.0 Packing unit: 2,000 pcs per bag Shur Plug type sleeves (female) Item No. L1.5 t0.2 R5025 2.5 3.8 5.0 2.6 23.0 33.0 1.0 R5028 2.8 4.0 5.0 2.8 23.0 33.0 1.0 R5030 3.2 4.3 5.2 3.0 23.0 33.0 1.0 R5035 3.5 4.5 5.0 3.0 23.0 33.0 1.0 R5040 4.0 4.8 5.5 2.8 23.5 33.0 1.0 R4028 2.8 3.7 4.0 2.8 23.0 32.0 1.0 Packing unit: 1,000 pcs per bag Shur Plug type sleeves (female) Item No. L1.5 t0.2 R5845 4.5 5.0 5.5 3.8 8.0 7.5 32.0 1.0 R3850 5.0 5.0 3.8 — 8.0 — 25.0 — POST-Insertion type Packing unit:1,000 pcs per bag Shur Plug type sleeves (male) Item No. L1.5 t0.2 R7025 2.5 7.3 3.6 3.0 17.0 27.0 1.0 R7028 2.8 7.0 3.8 3.0 18.0 27.0 1.0 R7035 3.5 7.3 3.5 2.3 19.5 30.0 1.0 Packing unit: 1,000 pcs per bag Three way type sleeves (female) Item No. L1.5 W1 W2 t0.2 P1250 3.0 5.0 4.0 10.5 24.0 37.0 5.0 12.0 1.0 Packing unit: 500 pcs per bag Two way type sleeve (female) Item No. L1.5 W1 W2 t0.2 S1225 2.5 3.6 3.5 25.5 35.0 12.0 4.5 1.0 S1232 3.2 4.0 3.0 26.0 35.0 12.0 4.5 1.0 S1240 4.0 5.2 3.5 25.5 35.0 12.0 4.5 1.0 Packing unit: 500 pcs per bag

Shur Plug type sleeves (male) Item No. L1.5 t0.2 R4225 2.5 3.8 5.0 2.5 4.5 14.0 1.0 R4228 2.7 3.7 5.0 2.8 4.5 15.0 1.0 R4230 3.0 4.1 5.2 2.8 4.5 15.0 1.0 R4235 3.5 4.4 5.3 3.0 4.5 16.0 1.0 R4240 4.0 4.7 5.5 3.0 4.5 14.5 1.0 R3528 2.8 3.3 3.8 3.0 4.5 14.0 1.0 Packing unit: 2,000 pcs per bag Shur Plug type sleeves (female) Item No. L1.5 t0.2 R5025 2.5 3.8 5.0 2.6 23.0 33.0 1.0 R5028 2.8 4.0 5.0 2.8 23.0 33.0 1.0 R5030 3.2 4.3 5.2 3.0 23.0 33.0 1.0 R5035 3.5 4.5 5.0 3.0 23.0 33.0 1.0 R5040 4.0 4.8 5.5 2.8 23.5 33.0 1.0 R4028 2.8 3.7 4.0 2.8 23.0 32.0 1.0 Packing unit: 1,000 pcs per bag Shur Plug type sleeves (female) Item No. L1.5 t0.2 R5845 4.5 5.0 5.5 3.8 8.0 7.5 32.0 1.0 R3850 5.0 5.0 3.8 — 8.0 — 25.0 — POST-Insertion type Packing unit:1,000 pcs per bag Shur Plug type sleeves (male) Item No. L1.5 t0.2 R7025 2.5 7.3 3.6 3.0 17.0 27.0 1.0 R7028 2.8 7.0 3.8 3.0 18.0 27.0 1.0 R7035 3.5 7.3 3.5 2.3 19.5 30.0 1.0 Packing unit: 1,000 pcs per bag Three way type sleeves (female) Item No. L1.5 W1 W2 t0.2 P1250 3.0 5.0 4.0 10.5 24.0 37.0 5.0 12.0 1.0 Packing unit: 500 pcs per bag Two way type sleeve (female) Item No. L1.5 W1 W2 t0.2 S1225 2.5 3.6 3.5 25.5 35.0 12.0 4.5 1.0 S1232 3.2 4.0 3.0 26.0 35.0 12.0 4.5 1.0 S1240 4.0 5.2 3.5 25.5 35.0 12.0 4.5 1.0 Packing unit: 500 pcs per bag

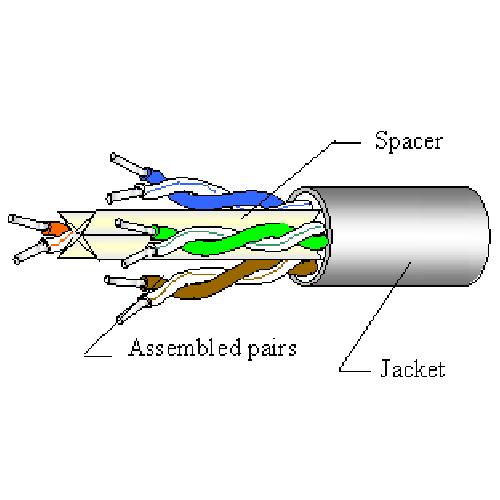

LAN CABLE is suitable for data transmission on Local Area Network , especially for computer, video or perfect audio. Specifications Application — AS Connecting media of Work Area Outlet to PCs, terminals, workstations and data equipments — Supporting 1000 Base - T Gigabit Ethernet, 550MHz Broadband video and 155 / 622 Mbps ATM with channel performance extended to 250MHz Configration — 24AWG solid copper for Horizontal cable — 24AWG stranded copper for patch cable — 4 pairs — Central Spacer — PVC/LSNH FRPE jacket — Packed with special designed paper reels and cartons Standards — TIA / EIA 568 - B2 - 1 — ISO / IEC - 11801 — CENELEC EN 50173 — CENELEC EN 50288 - 6 (for unscreened cable) — UL Subj. 444 — CSA C 22.2 NO. 214 Qualifications — Verified to TIA / EIA 568 - B.2 Category 6 by UL / CSA & ETL — Verified to TIA / EIA 568 - B.2 Category 6 by 3P Third Party Testing — Verified to ISO / IEC 11801 Category 6 by UL / CSA — UL / CSA & ETL approved CM / CMR Electrical Properties Charts Characteristic Impedance Attenuation ELFEXT (P-P) ELFEXT (PS) Delay NEXT (P-P) NEXT (PS) Return Loss Skew

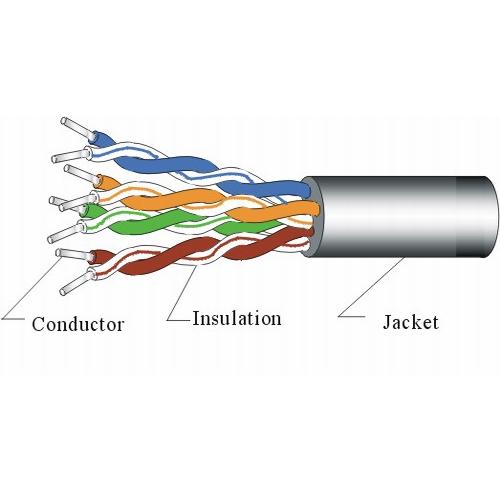

LAN CABLE is suitable for data transmission on Local Area Network , especially for computer, video or perfect audio. Specifications1. Wire: Pair No. Color 1P Blue ´ White/Blue Stripe 2P Orange ´ White/Orange Stripe 3P Green ´ White/Green Stripe 4P Brown ´ White/Brown Stripe 2. Specification: Conductor Material Copper Wire Structure 1 / 0.515 ± 0.007 mm Diameter Approx. 0.515 mm Insulation Material HDPE Average Thickness 0.2 mm Diameter 0.915 ± 0.05 mm Twisted Four pairs Assembly Arranged in accordance with the structure figure. Jacket Material PVC or LSOH Average Thickness 0.5 mm Diameter 5.2 ± 0.2 mm 3. Electrical Characteristics: Comply with TIA/EIA-568-B.2 Standard. Item Electrical Characteristics of Cable Impedance ( 1 – 100 MHz) 100 ± 15 Ω Conductor Resistance (20℃) 9.38 Ω Per 100 m (328 ft) Resistance Unbalance (20℃) Max. 5% Insulation Resistance (20℃) 1500MW - Km DC 500V (Between wire and ground) Dielectric strength DC 500V / 1min. or AC 350 V / 1min. Mutual Capacitance (1KHz) Max. 5.6 nF Per 100 m (328 ft) Capacitance unbalance (1KHz) 330 pF Per 100 m (328 ft) ( pair to ground) Delay Skew Max. 45 ns Per 100 m (328 ft) Frequency Insertion Loss (dB/100m) Max. Propagation Delay 0.772MHz 1.8 — 1 MHz 2.0 534 + 36/ √f (f:MHz) 4 MHz 4.1 8 MHz 5.8 10 MHz 6.5 16 MHz 8.2 20 MHz 9.3 25 MHz 10.4 31.25 MHz 11.7 62.5 MHz 17.0 100 MHz 22.0 Frequency NEXT (dB/100m) Min. PSNEXT (dB/100m) Min. ELFXT (dB/100m) Min. PSELFXT (dB/100m) Min. 0.772MHz 67.0 64.0 — — 1 MHz 65.3 62.3 63.8 60.8 4 MHz 56.3 53.3 51.7 48.7 8 MHz 51.8 48.8 45.7 42.7 10 MHz 50.3 47.3 43.8 40.8 16 MHz 47.3 44.4 39.7 36.7 20 MHz 45.8 42.8 37.7 34.7 25 MHz 44.3 41.3 35.8 32.8 31.25 MHz 42.9 39.9 33.9 30.9 62.5 MHz 36.4 35.4 27.8 24.6 100 MHz 35.3 32.3 23.8 20.8 Return Loss (dB/100m) 1≦ f <10MHz RL≧ 20+5.0 log(f) 10≦ f <20MHz RL≧ 25 20≦ f <100MHz RL≧ 25-7.0 log(f/20) 4. Packing: 305 Meters / Reel (8 type) in a box.

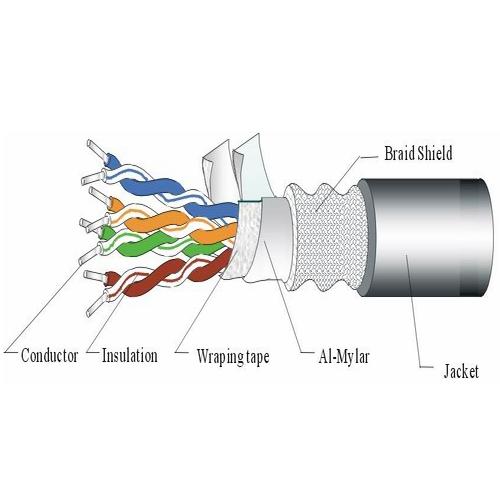

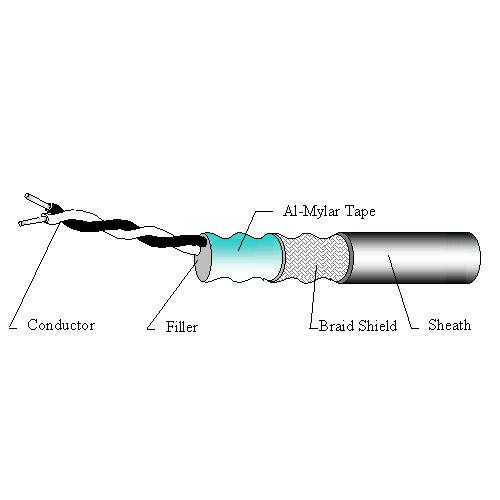

LAN CABLE is suitable for data transmission on Local Area Network , especially for computer, video or perfect audio. Specifications 1. Wire Construction: Pair Wire Arrangement 1 P Blue ´ White / Blue Stripe 2 P Orange ´ White / Orange Stripe 3 P Green ´ White / Green Stripe 4 P Brown ´ White / Brown Stripe 2. Structure: Item Specification Conductor Material Annealed Copper Construction 1 / 0.54 mm Diameter 0.54 ± 0.005 mm Insulation Material HDPE Average Thickness 0.247 mm Diameter 1.03 ± 0.02 mm Twisted Refer to structure figure Assembly Arranged in accordance with the structure figure. Non-woven tape Approx. 0.2 mm in thick. Al - Mylar Approx. 0.06mm in thick. (with Al side out) Braid Shield Material Annealed Tinned Copper Construction 24 / 8 / 0.12 mm Jacket Material PVC or LSOH Average Thickness 0.6 mm Diameter 6.9 ± 0.2 mm Packing 305 m plywood drum in a box 3. Electrical Characteristics: Comply with TIA/EIA-568-B.2 Standard. Item Electrical Characteristics of Cable Impedance (1 – 100 MHz) 100 ± 15 Ω Conductor Resistance (20℃) 9.38 Ω Per 100 m (328 ft) Resistance Unbalance (20℃) Max. 5% Insulation Resistance (20℃) 1500MW - Km DC 500V (Between wire and ground) Dielectric strength DC 500V / 1min. or AC 350 V / 1min. Mutual Capacitance (1KHz) Max. 5.6 nF Per 100 m (328 ft) Capacitance unbalance (1KHz) 330 pF Per 100 m (328 ft) ( pair to ground) Delay Skew Max. 45 ns Per 100 m (328 ft) Frequency Insertion Loss (dB/100m) Max. Propagation Delay 0.772MHz 1.8 — 1 MHz 2.0 534 + 36/ √f (f:MHz) 4 MHz 4.1 8 MHz 5.8 10 MHz 6.5 16 MHz 8.2 20 MHz 9.3 25 MHz 10.4 31.25 MHz 11.7 62.5 MHz 17.0 100 MHz 22.0 Frequency NEXT (dB/100m) Min. PSNEXT (dB/100m) Min. ELFXT (dB/100m) Min. PSELFXT (dB/100m) Min. 0.772MHz 67.0 64.0 — — 1 MHz 65.3 62.3 63.8 60.8 4 MHz 56.3 53.3 51.7 48.7 8 MHz 51.8 48.8 45.7 42.7 10 MHz 50.3 47.3 43.8 40.8 16 MHz 47.3 44.4 39.7 36.7 20 MHz 45.8 42.8 37.7 34.7 25 MHz 44.3 41.3 35.8 32.8 31.25 MHz 42.9 39.9 33.9 30.9 62.5 MHz 36.4 35.4 27.8 24.6 100 MHz 35.3 32.3 23.8 20.8 Return Loss (dB/100m) 1≦ f <10MHz RL≧ 20+5.0 log(f) 10≦ f <20MHz RL≧ 25 20≦ f <100MHz RL≧ 25-7.0 log(f/20)

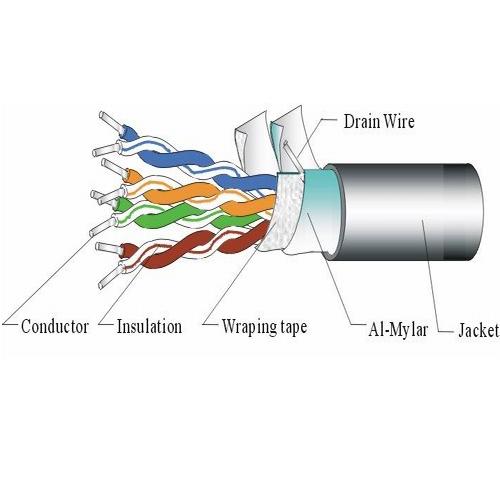

LAN CABLE is suitable for data transmission on Local Area Network , especially for computer, video or perfect audio. Specifications 1. Wire Construction: Pair Wire Arrangement 1 P Blue ´ White / Blue Stripe 2 P Orange ´ White / Orange Stripe 3 P Green ´ White / Green Stripe 4 P Brown ´ White / Brown Stripe 2. Structure: Item Specification Conductor Material Annealed Copper Construction 1 / 0.54 mm Diameter 0.54 ± 0.005 mm Insulation Material HDPE Average Thickness 0.247 mm Diameter 1.03 ± 0.02 mm Twisted Refer to structure figure Assembly Arranged in accordance with the structure figure. Non-woven tape Approx. 0.2 mm in thick. Drain Wire Material Annealed Tinned Copper Construction 1 / 0.515 mm Al - Mylar Approx. 0.06mm in thick. (with Al side in) Jacket Material PVC or LSOH Average Thickness 0.6 mm Diameter 6.3 ± 0.2 mm Packing 305 m plywood drum in a box 3. Electrical Characteristics: Comply with TIA/EIA-568-B.2 Standard. Item Electrical Characteristics of Cable Impedance ( 1 – 100 MHz) 100 ± 15 Ω Conductor Resistance (20℃) 9.38 Ω Per 100 m (328 ft) Resistance Unbalance (20℃) Max. 5% Insulation Resistance (20℃) 1500MW - Km DC 500V (Between wire and ground) Dielectric strength DC 500V / 1min. or AC 350 V / 1min. Mutual Capacitance (1KHz) Max. 5.6 nF Per 100 m (328 ft) Capacitance unbalance (1KHz) 330 pF Per 100 m (328 ft) ( pair to ground) Delay Skew Max. 45 ns Per 100 m (328 ft) Frequency Insertion Loss (dB/100m) Max. Propagation Delay 0.772MHz 1.8 — 1 MHz 2.0 534 + 36/ √f (f:MHz) 4 MHz 4.1 8 MHz 5.8 10 MHz 6.5 16 MHz 8.2 20 MHz 9.3 25 MHz 10.4 31.25 MHz 11.7 62.5 MHz 17.0 100 MHz 22.0 Frequency NEXT (dB/100m) Min. PSNEXT (dB/100m) Min. ELFXT (dB/100m) Min. PSELFXT (dB/100m) Min. 0.772MHz 67.0 64.0 — — 1 MHz 65.3 62.3 63.8 60.8 4 MHz 56.3 53.3 51.7 48.7 8 MHz 51.8 48.8 45.7 42.7 10 MHz 50.3 47.3 43.8 40.8 16 MHz 47.3 44.4 39.7 36.7 20 MHz 45.8 42.8 37.7 34.7 25 MHz 44.3 41.3 35.8 32.8 31.25 MHz 42.9 39.9 33.9 30.9 62.5 MHz 36.4 35.4 27.8 24.6 100 MHz 35.3 32.3 23.8 20.8 Return Loss (dB/100m) 1≦ f <10MHz RL≧ 20+5.0 log(f) 10≦ f <20MHz RL≧ 25 20≦ f <100MHz RL≧ 25-7.0 log(f/20)

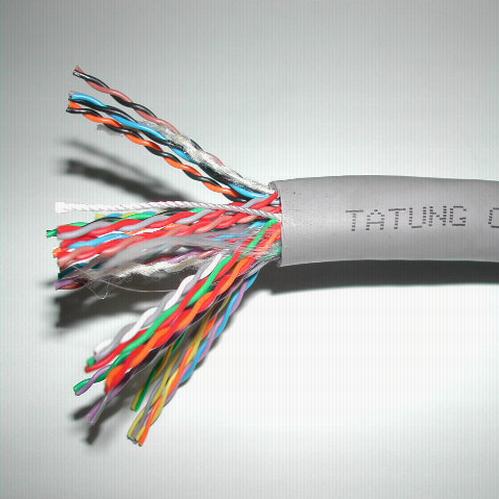

LAN CABLE is suitable for data transmission on Local Area Network , especially for computer, video or perfect audio. Specifications 1. Wire Construction: Pair Wire Arrangement Pair Wire Arrangement 1 P Blue ´ White 14 P Brown ´ Black 2 P Orange ´ White 15 P Gray ´ Black 3 P Green ´ White 16 P Blue ´ Yellow 4 P Brown ´ White 17 P Orange ´ Yellow 5 P Gray ´ White 18 P Green ´ Yellow 6 P Blue ´ Red 19 P Brown ´ Yellow 7 P Orange ´ Red 20 P Gray ´ Yellow 8 P Green ´ Red 21 P Blue ´ Violet 9 P Brown ´ Red 22 P Orange ´ Violet 10 P Gray ´ Red 23 P Green ´ Violet 11 P Blue ´ Black 24 P Brown ´ Violet 12 P Orange ´ Black 25 P Gray ´ Violet 13 P Green ´ Black 25P: with no color tape 50P: 1P~25P unit is wrapped with one white tape and one blue tape, 26P~50P unit with white and orange 100P:1P ~ 25P unit is wrapped with one white tape and one blue tape, 26P ~ 50P unit with white and orange, 51P ~ 75P unit with white and green 76P ~ 100P unit with white and brown. 2. Structure Item Specification Conductor Material Annealed Copper Construction 1 / 0.52 mm Diameter Approx. 0.52 mm Insulation Material HDPE Average Thickness Approx. 0.2 mm Diameter 0.92 ± 0.05 mm Twisted Refer to structure figure Assembly Arranged in accordance with the structure figure. Jacket Material PVC or LSOH Average Thickness Approx. 1.0 mm Diameter (25P) Approx. 14.0 mm Diameter (50P) Approx. 14.0 × 26.0 mm Diameter (100P) Approx. 31.0 mm 3. Electrical Characteristics: Comply with TIA/EIA-568-B.2 Standard. Item Electrical Characteristics of Cable Impedance ( 1 – 100 MHz) 100 ± 15 Ω Conductor Resistance ( 20℃ ) 9.38 Ω Per 100 m ( 328 ft ) Resistance Unbalance ( 20℃ ) Max. 5% Insulation Resistance ( 20℃ ) 1500M W - Km DC 500V (Between wire and ground) Dielectric strength DC 500V / 1min. or AC 350 V / 1min. Mutual Capacitance (1KHz) Max. 5.6 nF Per 100 m ( 328 ft ) Capacitance unbalance (1KHz) 330 pF Per 100 m ( 328 ft ) ( pair to ground) Delay Skew Max. 45 ns Per 100 m ( 328 ft ) Frequency Insertion Loss (dB/ 100m ) Max. Propagation Delay 0.772MHz 1.8 — 1 MHz 2.0 534 + 36/ √f (f:MHz) 4 MHz 4.1 8 MHz 5.8 10 MHz 6.5 16 MHz 8.2 20 MHz 9.3 25 MHz 10.4 31.25 MHz 11.7 62.5 MHz 17.0 100 MHz 22.0 Frequency NEXT (dB/ 100m ) Min. PSNEXT (dB/ 100m ) Min. ELFXT (dB/ 100m ) Min. PSELFXT (dB/ 100m ) Min. 0.772MHz 67.0 64.0 — — 1 MHz 65.3 62.3 63.8 60.8 4 MHz 56.3 53.3 51.7 48.7 8 MHz 51.8 48.8 45.7 42.7 10 MHz 50.3 47.3 43.8 40.8 16 MHz 47.3 44.4 39.7 36.7 20 MHz 45.8 42.8 37.7 34.7 25 MHz 44.3 41.3 35.8 32.8 31.25 MHz 42.9 39.9 33.9 30.9 62.5 MHz 36.4 35.4 27.8 24.6 100 MHz 35.3 32.3 23.8 20.8 Return Loss (dB/ 100m ) 1≦ f <10MHz RL≧ 20+5.0 log(f) 10≦ f <20MHz RL≧ 25

Optionally supports output of Dolby True HD and DTS-HD Master Audio streams for external decoding by AV receivers.( TrueHD and DTS-HD are lossless audio codec formats used on Bly-ray Discs and HD DVDs . ) Specifications Optionally supports output of Dolby True HD and DTS-HD Master Audio streams for external decoding by AV receivers.( TrueHD and DTS-HD are lossless audio codec formats used on Bly-ray Discs and HD DVDs . ) 1. Construction Differential signal Control and other signal Conductor Material - Silver coated annealed copper wire Tin coated annealed copper wire Diameter mm Approx. 0.254 (Size:30AWG) Insulation Material - Foam PE PE Color - White , Red Green , White , Red Diameter mm Approx. 0.7 Approx. 0.5 Twisting Composition - Two insulated conductors (White-wire and Red-wire) shall be uniformly twisted together. - Shield Composition 4 sets of twisted pairs, 4 sets of drain lines and 7 sets of control lines are arranged in alignment as shown in the attached drawing and wrapped by a shield tape. Shield tapes are also inserted between the twisted pairs, separating each pair. There should not be gaps in the wrapping shield tape and in the shield tapes between the twisted pairs. Also, both the ends of the wrapping shield should be glued without gaps, and the edged part glued should be neatly cut without forming a projection. Kind - For outsides : Aluminum Polyester Laminating Tape For inside : Aluminum Polyester Aluminum Laminating Tape Thickness mm For outsides : 0.025 (Al : 0.006) For inside : 0.03 (Al : 0.006) Drain Material - Tin coated annealed copper wire Diameter mm Approx. 0.254 (Size : 30AWG) Jacket Material - PVC Color - Black Thickness mm Nom. 0.5 Overall diameter mm H*W=1.85 ´ 11.5 ( ± 0.1 ) Marking E54979 AWM 20276 80℃ 30V VW-1 TATUNG - HDMI 2. Rating Rating Voltage V 30 Rating Temperature ℃ 80 3. Performance Electrical Requirements Conductor resistance Ω/km Max.361 ( at 20℃ ) Dielectric strength V-min To withstand 300 Volts R.M.S. for one minute. (Between all interconnected conductors, and all the interconnected shields.) Insulation resistance (Between conductor and earth) MΩkm Min. 10 This measurement shall be made with 150 volts D.C. after steady electrification for one minute. (During the tests, remaining conductors shall be connected to earth.) Differential impedance Ω Cable Area 100±10 Connector Area 100±15 Delay* ns/m Max. 5.05 Inter-Pair Skew* ns Max. 2.42 Intra-Pair Skew* ps Max. 151 Far-end crosstalk* dB Max. -26 dB (f=300k~5000MHz) Insertion Loss* dB Min. - 8 dB (f=300k~825MHz) Min. -21 dB (f=825M~2475MHz) Min. -30 dB (f=2475M~4125MHz) Capacitance** pF Max. 700 *Differential signal line **Between Pin No.15 to No.17 and No.16 to No.17 4. Cable FLAME TEST To conform to UL 1581 VW-1 combustion test. 5. RoHS Regulation Material name Rated value Cadmium and Cadmium Compounds 75ppm Hexavalent Chromium Compounds 1000ppm Lead and Lead Compounds 300ppm Mercury and Mercury Compounds 1000ppm PBB (Polybrominated Biphenyls) 1000ppm PBDE(Polybrominated Diphenyl Ethers) 1000ppm 6. Cable Wire Assignment Pin Color Cable Function 1 Red TMDS Data 2+ 3 White Green 2 Drain TMDS Data 2 Shield 4 Red TMDS Data 1+ 6 White TMDS Data 1- 5 Drain TMDS Data 1 Shield 7 Red TMDS Data 1 Shield 9 Red TMDS Data 0- 8 Drain TMDS Data 0 Shield 10 Red TMDS Data Clock+ 12 White TMDS Data Clock- 11 Drain TMDS Clock Shield 13 Green CEC 14 Red Reserved(N.C. on device) 15 White SCL 16 Green SDA 17 Red DDC/CEC Ground 18 Red +5V Power 19 White +5V Power

1.Inner wiring of computers and videos.2.Special designs are subject to customers' requirements. Specifications 1.Conductor:Tinned Copper Strand. 2.Insulation:HDPE ( High Density Polyethylene)3.Wrapping Shield:Bare or Tinned Copper on Strand4.Sheath:PVC(Polyvinyl Chloride) 5.Structure: Conductor Insulation (Twist) AWG Construction Diameter Min.Thickness Nominal Thickness Diameter 30 7 / 0.10TA approx.0.30mm 0.31mm 0.15mm 0.60 ± 0.03mm Assembly Braid Shield Sheath ConductorResistantce(20℃) # 30 (7 / 0.10TA) ConstructionThickness DiameterThickness Min Nominal Diameter Cotton Yarn Filler Al-mylar Tape 0.025X20 mm 16 / 8 / 0.10 approx.0.30mm 0.31mm 0.15mm 0.60 ± 0.03mm Max.362.88W/Km 6.Characteristics: Items Specification Rating UL:80℃ 30V Dielectric Strength Spark Test AC2000V / min. Insulation Resistance Min.5MW - Km (20℃) at DC 500V Flame Test UL:VW – 1 7.Marking:E54979 AWM 20276 80℃ VW – 1